Refrigerant lines

Refrigerant flow

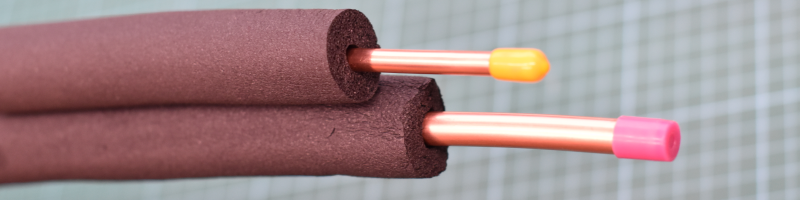

Mini-split indoor and outdoor units are connected with two copper pipes (called the line set). They are two different sizes. The larger is known as the vapour or suction line, and the smaller is called the liquid line.

The direction of refrigerant flow changes direction depending on whether the system is cooling or heating. This means that the lines can be carrying either:

- low temperature, low pressure refrigerant to and from the indoor heat exchanger which is acting as a evaporator (cooling mode), or

- high temperature, high pressure refrigerant to and from the indoor heat exchanger which is acting as a condenser (heating mode).

The line set

Because the line set can be operating at either low or high temperatures and pressures it is important to:

- Ensure both lines are insulated well.

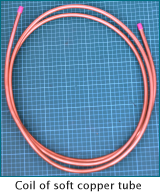

- Use refrigerant rated copper tubing. This is thicker and has a higher-pressure rating than standard water pipework. Tubing comes either as lengths of straight ‘hard’ copper tube or coils of soft copper tube. The latter is commonly used in mini-split installation because it is easier to bend and work with.

- Not solder, but braze any pipe joins. However, such joints should be avoided wherever possible - coils of copper tube are available in lengths of up to 30m.

Mini-split units up to 3.5 kW typically have line sizes of 1/4 inch and 3/8 inch. 5 kW units often use 1/4 inch and 1/2 inch pipes. There are exceptions though, so do check the manufacturer’s specifications.

Handling and installation tips

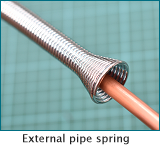

- When bending tubes

Always use a tube bender (expensive) or an external spring (cheap). Be very careful not to kink the tubing. There are lots of tutorials on the web, including this one from AC Service Tech

Always use a tube bender (expensive) or an external spring (cheap). Be very careful not to kink the tubing. There are lots of tutorials on the web, including this one from AC Service Tech .

- Leave plenty of extra tubing for flaring

The tubing connections are formed by flaring the ends of the pipes at 45°. Checkmark does this as part of the connection service, keeping the installation legally compliant and saving you the purchase of specialist tools. - Allow flex in the pipes

The refrigerant lines are subject to expansion, contraction and stress from the heating and cooling of the system. Many installers leave a loop of pipe behind the outdoor unit allow for these factors. It is also useful should a flare need to be re-done. - End caps

Coils of soft copper tubing come with plastic end-caps to prevent the entry of moisture and debris. It is good practice to keep these in place on the lines during preparatory work. - Insulation

Insulation is available as slide on sleeving or wrap round tape. Pipes can also come pre-insulated. Additional wrap around insulation can be used over pipe sleeving. - Trunking and ducting

Dedicated trunking and ducting can be used on both internal and external pipework to provide additional protection and improve the appearance.

It is important to leave room for the pipework to be adjusted should it become necessary to redo the flares at either the internal or external unit. Ducting covers etc. should be left open until the line set is fully connected and operational.

Remember

It is against the law to make the connections to either the indoor or outdoor units if you do not have the correct qualifications. You could receive a civil penalty for breaking the law.Checkmark is fully qualified in F-gas handling. We provide a professional commissioning service. You do the preparation and physical mounting of the equipment but must not touch the refrigerant or F-gas connections.